Commentary on joints

Today, we’ll be discussing ‘Knife Joints.’ I will provide a clear and easy-to-understand explanation of the term ‘joints’ as it relates to the knives I use.

‘Joint’ refers to the subtle angle changes within the blade structure that can occur based on the sharpening angle. It is something that may not be easily visible to the naked eye but can be felt distinctly when the blade is sharpened on a finishing stone.

When using a medium or coarse sharpening stone, the slurry of the stone tends to obscure the joints.

The ‘sharpening angle’ that I mentioned is achieved by the sharpener during the manufacturing process.

To avoid any misinterpretation, let me provide a detailed explanation.

There are knives (made by blacksmiths) that can be sharpened without changing the sharpening angle. And there are also sharpeners who can minimize the variation in sharpening angles to an extreme level, even for knives that do exhibit tapering from the tip or blade base towards the cutting edge.

In general, knives have a tapering shape from the blade tip or heel towards the cutting edge, which naturally results in a variation in sharpening angles. Unless we are discussing extremely fine details, it is considered normal.

Now, let me emphasize an important point: knives have a three-dimensional (3D) structure, not just a flat two-dimensional (2D) surface.

The areas where the sharpening angle changes are slightly below the tip’s radius and the heel section.

Now, let’s address the question of why the sharpening angle is altered and resolve any doubts.

The main factor is to create a structure where the blade becomes thinner from the heel to the tip. “You might think, ‘Why not create a taper uniformly from the base to the tip through sharpening?'” In reality, it does happen, but there is another factor that comes into play…

As the blade gets thinner towards the tip, we also need to ensure that the cutting edge width remains uniform. This introduces the process of creating a ‘tip draw’.

When we delve into the details, as the blade tapers towards the tip, there is a process of widening the cutting edge. For those wondering ‘How is it widened?’ it is done by expanding towards the shinogi side. Angle manipulation is involved to achieve the alignment of the cutting edge width and the creation of the tip draw.

To resolve this, it may be possible to create a blade with a consistent thickness from the heel to the tip. However, that would result in a knife that is difficult to use as a tool. In blunt terms, it would become a knife with an excessively heavy tip, similar to a hatchet.

The above reasons explain why we create the joints (angle changes).

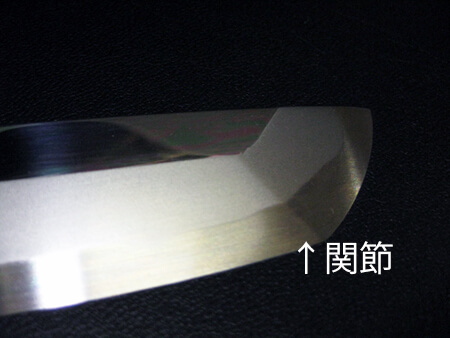

The label in the photo says ‘Joint’.

It’s an extreme example, but I attached an image using the tip of a Sakimaru Takohiki knife. While Yanagi knives may not have such a pronounced straight line, I believe it helps to grasp the concept of joint through the change in sharpening angles. The tip is the tip, giving a distinct impression.

Now, let’s talk about the negative effects of this joint and what happens if we ignore it. If we continue sharpening forcefully without paying attention to the joint (change in sharpening angles), the knife’s edge will become completely straight, resulting in a ‘Tsuru-Neck’ blade. Additionally, if we disregard the angle and forcefully continue sharpening, the area around the tip’s Shinogi line may not make contact with the sharpening stone, leading to the distortion of the tip’s arc.

One way to avoid these issues is to divide the knife into three sections:

- From the tip to the beginning of the tip’s arc

- The middle section of the blade

- The base of the blade

By sharpening each section separately, we can maintain the knife’s original shape. In other words, the goal is for the sharpener to follow the angles initially created during the sharpening process and skillfully blend any slight changes in angle to achieve a seamless transition.

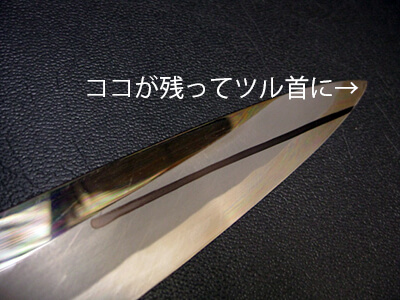

The label in the photo says, “This area is left behind and becomes a ‘Tsuru-Neck.'”

The knife in the photo does not have a joint along the solid black line, but typically, joints like this can be found in many cases. The specific location of the joint can vary depending on the sharpener and individual differences, so please consider it as an example.

If you forcefully continue sharpening, a section may remain, resulting in a “Tsuru-Neck” or a hollow in the edge. In the photo of the knife, there is also a section around the Shinogi line where the sharpening stone did not make contact. While there are methods to remove these sections during sharpening, I choose to leave them as they are within the reachable range of sharpening to ensure that others can continue sharpening without difficulty.

I have the most opportunities to sharpen brand-new knives, and my mission is to deliver them without altering their shape in any way. Therefore, I make an effort to be mindful of the angles set by the blade sharpener, while ensuring that customers don’t need to worry about it too much… or rather, I strive to smoothly remove any angle changes and deliver the knives. This is in reference to Honbaduke. It’s like creating guidelines within my capabilities!

For me, the ‘negative impact of joints’ refers to anything that hinders maintaining the knife’s original shape. Just to clarify, regarding these joints, I believe that unless all the areas where angle changes occur are sharpened away, they will continue to persist. By ‘sharpening away,’ I mean either shortening the tip portion or making the cutting edge straight. However, this can vary depending on the individual knife, so I cannot make a definitive statement about it.

For chefs as well, the situation is the same. They want to maintain the original shape of the knife, but there is a possibility that the ‘joints’ may have a negative impact by altering the shape. The conversation has gradually shifted from joints to the discussion about the overall shape. It has actually moved beyond the topic of joints.

Now, let’s discuss the potential negative impacts of this ‘joint’ (the apex of the sharpening angle). Personally, I believe that the most significant impact is the inability to achieve a clean sharpening surface. When working with finishing stones, the presence of the ‘joint’ can interfere with achieving smoothness. For those who sharpen knives as a hobby, many of them strive to achieve a beautifully finished tip.

In the case of chefs, it is honestly unclear how this ‘joint’ specifically affects their work. Does the raised joint hinder the cutting process? But then again, traditional Japanese knives are primarily used for cutting on the backside, so perhaps it is irrelevant? Or does the lack of a clean tip curvature interfere with their cooking? It remains to be fully understood.

However, it is not uncommon to see in online photos that some people sharpen the tip separately and the blade belly separately. The area where the ‘joint’ is present may have a more angular shape, which can make it less comfortable to use the corner, but it may be intentional to achieve a specific smooth curvature. If someone desires a smooth curvature, then the ‘joint’ can be seen as an obstruction…

There is also a possibility that when identifying the ‘joint’ and sharpening it, one may over-sharpen and unintentionally change the shape! Those who sharpen different areas separately might have a good understanding of the knife’s structure or they may intentionally reshape it to make it easier to cut nori seaweed or to prevent sticking. However, the specific details are unknown.

There are various patterns, and it’s challenging to grasp all of them. The conversation has gone off in different directions, but all these points revolve around the concept of the ‘joint’.

Some people might find the information I’ve mentioned earlier a bit confusing. I believe that there are also individuals who can achieve a clean sharpening without going through those specific steps. Those who can sharpen effectively may do so naturally or instinctively, adapting to the process without consciously following a specific method. I understand that there are various opinions on this matter, and at this moment, this is how I personally perceive it.

By the way, the knives that have been carefully crafted with consideration for both the “joint” and the taper to maintain the shape and ease of sharpening are SUISIN DENSHO and HONKASUMI+. When you make a purchase, although the knives may fall under the same category of “chef’s knives,” you will begin to notice the differences after one or two years.

That’s just a friendly reminder from a sales perspective. (^^)b

hibishugyo 2013-06-21