Matching the Deba Knife

We had a deep conversation with the customer about selecting a Deba knife. We discussed the importance of achieving a clean and sharp edge, characterized by a well-defined Shinogi line and a clean uraoshi bevel. To address this, we recommended the Honkasumi Plus finish!

In terms of steel material, we considered ease of sharpening and frequency of use, and we suggested the Shirogami 2 steel.

For handle material, we explained the different options such as ho wood and ebony, highlighting their durability and grip characteristics. The customer made their selection based on their preferences.

Blade dimensions proved to be the most challenging aspect. We advised that the size of the Deba knife should align with the size of the fish being handled. The customer mentioned handling small fish regularly but occasionally dealing with larger ones. Considering the convenience of performing head splitting, we suggested opting for a larger Deba knife that would also serve well for that purpose. As a result, they decided on the 180mm Kishubusshin Deba knife.

We have also received requests for Honbaduke sharpening.

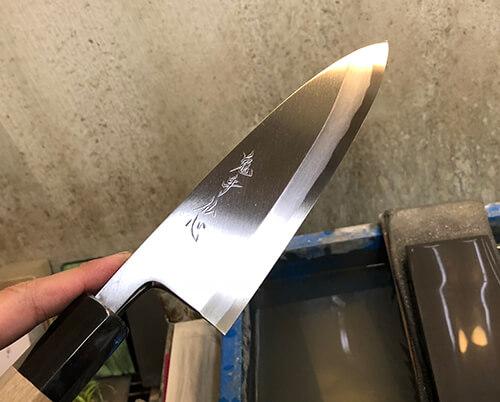

Introducing the ‘Kishubusshin,’ a knife that incorporates the Honkasumi Plus finish into its blade structure. From the moment we started discussing knife options, we knew this one was a winner!

As per your specification for a Hamaguri edge, we crafted the steel portion of the blade with a Hamaguri grind. The area near the Shinogi line has been meticulously sharpened, resulting in outstanding cutting performance beyond the Hamaguri edge.”

Please note that in English, we typically use the term “convex edge” instead of “Hamaguri edge.

I imagine that when customers sharpen the knife themselves, focusing on the steel part (dedicating themselves to creating the edge), the cutting edge structure will gradually develop over time.

As always, it maintains a stable “uraoshi” state. It possesses the beauty comparable to a Yanagiba knife!

I took some unnecessary photos, but this time I tried using the ‘Arashiyama’ sharpening stone. It’s not as symmetrical as the ‘Kitayama’ stone, but it adds some color to the article (smiles). I believe the knife has been finished according to your request. It is scheduled to arrive tonight. I would be delighted if you are pleased with it!

Sharpening notes: Sharpening stones used:

Cutting edge:

- Diamond #500

- Diamond #1000

- Medium finishing stone #4000

- Super finishing stone #10000Itohiki edge:

- Super finishing stone #10000Uraoshi (back side):

- Diamond #1000

- Super finishing stone #10000

I have used the super finishing stone #10000 extensively, primarily for achieving a glossy finish and removing any ‘kaeri’ (burr), as well as creating a fine Itohiki edge. Generally, I use the #10000 stone once the initial edge has been formed.

In practice, stable edges can be achieved using the ‘Kitayama’ or ‘Arashiyama’ stones, or even the Shapton #8000 stone.”

Please note that ‘kaeri’ refers to the burr or wire edge that forms during sharpening.

hibishugyo 2017-12-06